Advanced Manufacturing

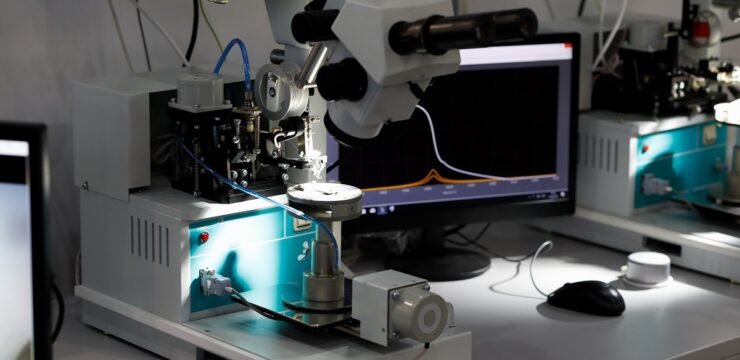

Quality control is one of the most crucial elements of modern manufacturing, especially where high-precision design and fabrication techniques have given way to very low tolerances throughout the manufacturing process. In many applications, components manufactured to a fraction of a…

Read MoreSecondary manufacturing processes are those processes that are done after the initial manufacturing processes—like injection molding, CNC machining production, and so on. As the name suggests, these processes are used to refine the workpiece in some manner. It is important…

Read MoreLaszeray Technology, LLC to Manufacture Ventilators for STARK Industries, LLC Awarded NASA JPL – VITAL Ventilator Manufacturing License to Combat the Global COVID-19 Crisis STARK Industries awarded a global license by NASA JPL Caltech to manufacture, assemble, distribute, sell, and…

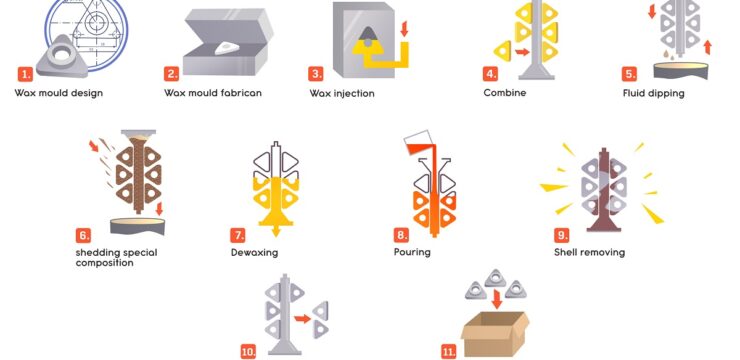

Read MoreInvestment casting is one option for creating intricate parts and components. There are several specific steps in the entire process to design and create the desired workpieces. It is named such because the workpieces are created around a shelled casting,…

Read MoreWhen it comes to producing finished goods using injection molding processes, one option is called overmolding. This process results in a single finished workpiece being produced using a combination of molding steps where at least two types of plastic materials—or…

Read MoreDrop shipping allows businesses to outsource major components of their manufacturing and fulfillment processes. In doing so, businesses can avoid having to manufacture and ship products in-house, potentially saving thousands of dollars on facilities, equipment, and labor. While the benefits…

Read MoreIt’s the year 2020, and many businesses around the globe have added robots as part of their workforce. Walmart uses them for cleaning stores while automobile factories use them for robotic part handling to speed up assembly line processes. While…

Read MoreOne of the exciting things about offering rapid prototyping services to our clients is the ever-changing nature of the work. We never quite know what will come our way, so it’s important to be as flexible and versatile as possible.…

Read MoreLaser engraving is one of several different secondary finishing operations in manufacturing that can be used to put the “finishing” touches on parts, components, and various products. As its name implies, laser engraving uses high-powered lasers to carefully remove material from the…

Read MoreSpin welding is a process used with various types of plastics, especially those with thermoplastic properties, which means the plastic can be melted, shaped, and formed without losing its strength and durability. It requires using special friction welding equipment or…

Read More