Custom Plastic Injection Molding

Injection molding has been around for about 150 years, but modern advances bring precision, efficiency, and cost-effectiveness to this staple of manufacturing. So, what is plastic injection molding, and how can it provide quality, precision, and cost-effective parts for your manufacturing processes?

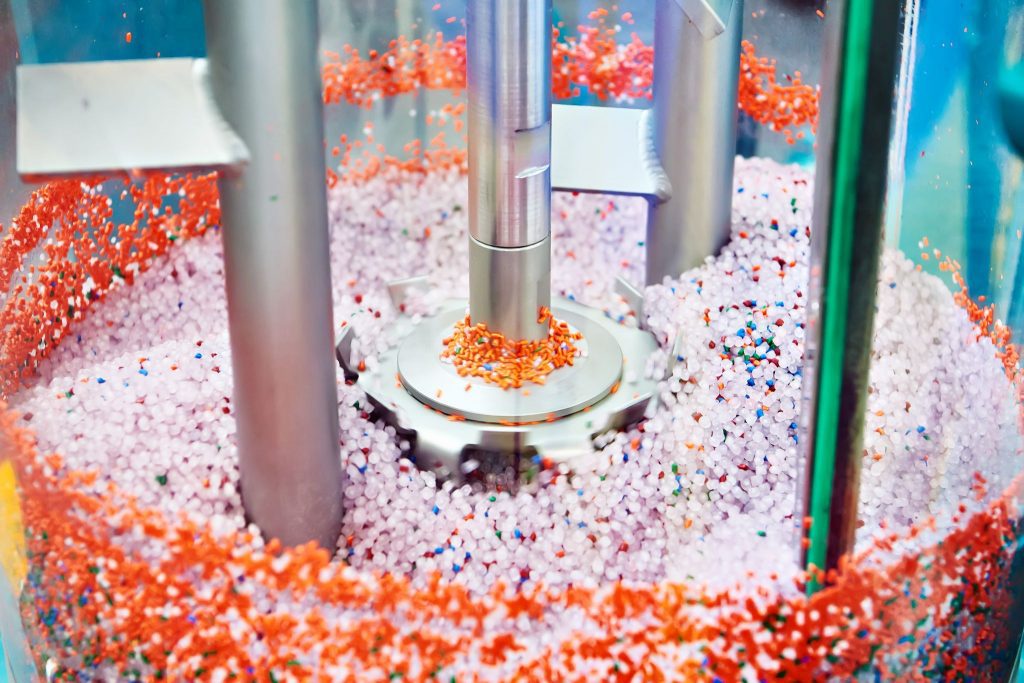

The process of injection molding involves injecting different melted materials into a mold where they quickly cool and are ejected as finished, hardened manufactured components. The ability of injection molding companies to produce several components that are accurately sized in just seconds makes the cost of plastic injection molding an efficient way to produce several different kinds of components. Materials used in the injection molding process include glass, thermoplastics, resins and polymers into precisely shaped products and product parts.

Continuing innovations mean that over 18,000 materials can be used in the injection molding process, so manufacturers can choose the material that works best for their products and product parts. Whether you use glass, resin, or plastic for your injection molding products, the fundamentals of the plastic and metal injection molding processes are similar. Depending on the materials used and the complexity of the end result, there can be wide variations in injection molding costs. However, working with a knowledgeable manufacturing partner who understands the nuances of adjusting the manufacturing process will get you the most out of the materials used and could reduce the cost of plastic injection molding.

One of the most experienced and knowledgeable plastic injection molding companies in Ohio, or in the U.S. for that matter, has the experience in plastic injection molding that will meet the needs of your projects. When searching for “plastic injection molding companies near me” be sure to visit websites that will help you determine which injection molding companies are qualified to handle your materials and produce the results you require.

Plastic Injection Molding for Fast-paced Production

The evolution of the plastic injection molding machine has made plastic injection molding products easier to produce, more durable, and increasingly less expensive. Like so many other industries, as the cost of technology has decreased, so has the cost of plastic injection molding. But also similar to technology trends, the quality, reliability, and speed of production for plastic injection molding has increased, even as the cost goes down. Working with plastic injection molding companies that meticulously assist in planning your plastic injection molding project will bring you into a collaborative process that ensures success.

Modern Production with Injection Molding Machines

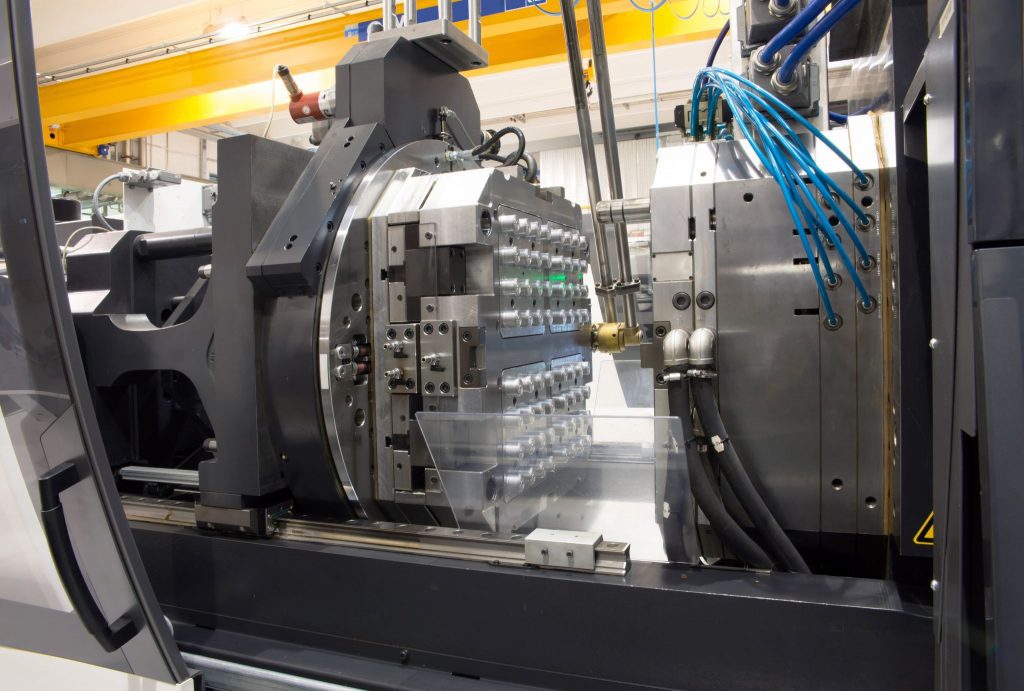

The functions of plastic injection molding machines may have evolved some over time, but they all essentially have three different parts to them: the mold, clamps, and an injection unit. As part of the 20th century developments in the injection molding process, the injection unit includes a heated barrel and a screw mechanism that feeds the materials used, usually in the form of small pellets or beads. As materials advance up through the injection unit, they are heated until they are pushed, in melted form, into the molds.

While the machine is certainly doing all the work at this point, working with an injection molding company that can translate your manufacturing components to accurate and efficiently produced parts is important. An integrated engineering team as a part of the injection molding company that you choose is vital. This will ensure that molding is done in a way that considers ideal materials properties, and the best size, shape, and layout of the mold. This will also help guarantee that the best plastic injection molding machine is used for your manufacturing needs.

Understanding the Cost of Injection Molding

Injection molding costs vary according to the size, complexity, quantities needed, and materials used. While there is a wide range of costs associated with injection molding, it can still be a very cost-efficient production method. For the development of simpler, smaller molds, this lower cost can make injection molding ideal for developing a small number of initial prototypes.

As your injection molding projects become more advanced, you need to understand more than just injection molding cost. For companies that attempt to low-ball the cost, you may be sacrificing the expertise of highly trained specialists who understand the importance of the right machine and properly mixed materials for each project. This could cost your project unnecessary expense and delays.

Experienced Injection Molding Companies

While many plastic injection molding companies can produce basic designs in plastic that are easily replicable, it takes a more experienced injection molding company with specialized plastic injection molding machines to bring more complicated designs to fruition. Experienced companies will not only understand the manufacturing process, but also provide the engineering consultation services, refined injection molding cost estimations, and the materials’ management that can protect your supply chain for the long run.

Be sure to ask questions about the complexity of projects in the portfolio of the injection molding company that you consider. Think about the different materials they have experience with and the variety of machinery that can be used to produce the best results. When it comes to plastic injection machines, there are no one-size-fits-all solutions.

Laszeray manufactures a wide range of custom plastic injection molded components from nearly any type of engineered resin plastics. Our custom plastic injection molding equipment is capable of processing more than 250 different materials. As a top company, our facility and staff can handle any job, from low-volume short runs to high-volume runs of consumer products that number in the millions of units. Laszeray’s precision systems can create plastic parts in a broad spectrum of sizes and degrees of complexity. We have expertise in manufacturing appearance parts and molding of Eastman Tritan™ co-polyester. We’re one of the most versatile custom plastic parts manufacturers active today.

Quality Molded Plastic Part Manufacturing

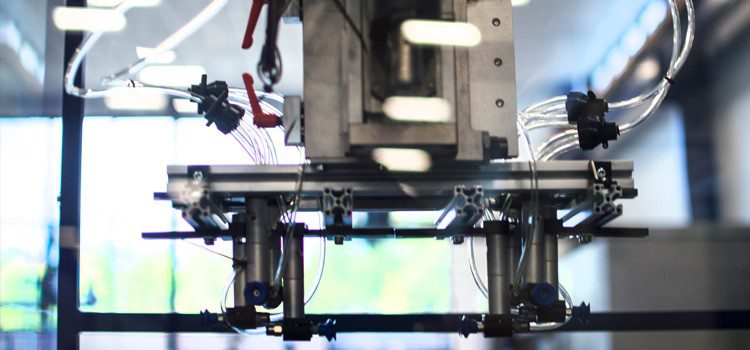

Our highly automated plastic molding manufacturing equipment utilizes robotic part handling, trimming, and pad printing to ensure quality and consistency. Secondary operations that include ultrasonic or spin welding, labeling, and kitting are added value services we offer to our customers.

We focus on client relationships and quality production. Our state-of-the-art manufacturing facility houses not only precision injection molding presses, but also an in-house tool shop for production and ongoing maintenance of molds. We have a fully staffed engineering team to conceive and produce top-quality designs, manufacturing capabilities to develop OEM product, and warehouse storage space to maintain customer inventory.

As part of our desire to be first and foremost among custom plastic mold manufacturers, we’re always willing to hear from our customers. Feel free to contact us for more information on our manufacturing services.

LASZERAY’S MOLD CAPABILITIES INCLUDE:

Being centrally located, we are also within 600 miles of half the populations in the U.S. and Canada. We have an array of plastic injection molding machines to serve customers who require precision and are mindful of the cost of injection molding in the manufacturing of their components.