Injection Mold Tool Manufacturing

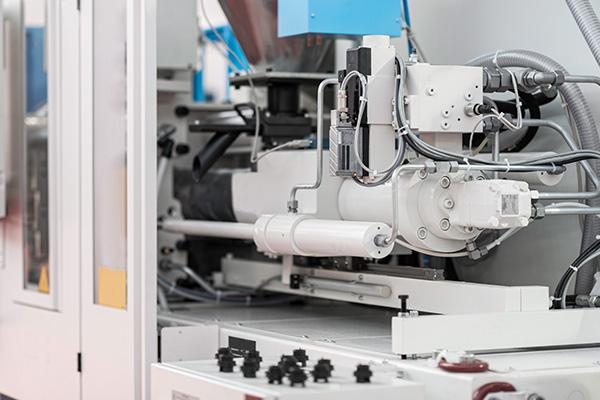

Injection molding is the preferred method for manufacturing plastic parts. But to have a good part, you first must have a good mold. For that reason, an experienced injection mold tool design team—one that knows how to minimize expenses involved in the tool design and manufacturing process while producing parts of high quality—can mean the difference between success and failure for your project. Laszeray Technology is an industry leader in plastic injection mold design engineering and manufacturing.

Laszeray’s team of engineers will optimize the mold design and selected material for injection molding to ensure that a suitable product can be manufactured. Once a product’s design has been conceptualized, our rapid prototyping process provides customers a full-scale prototype of the product within hours. This can be achieved by 3D printing or initial production tooling capable of generating low-volume production runs. These capabilities allow customers to evaluate the function and appearance of their new product’s design and increase speed to market quickly and fully.

Once the product design is approved, we move on to generating the molding design, making sure the mold flow analysis is optimal. We offer quick turnaround and maximum versatility by building your plastic injection mold tooling either in-house or through our global network of partners. Additionally, on-site repair and maintenance of customer tooling eliminates the distractions and inefficient processing that commonly result from the use of outside vendors. Laszeray provides turnkey solutions for businesses that need world-class injection mold tooling. Feel free to contact us if you have questions about our plastic injection mold design and manufacturing services that are not answered in this section.

What Manufacturers Should Know About Injection Mold Tool Design

Designing plastic injection mold tools is a complex task involving a wide range of factors. It is critical that ongoing, clear communication take place between your team and the plastic injection mold tool design engineers that will be responsible for understanding how your parts will be used, how they will work with other parts, the loads it will experience, structural and functional components, and what the end user experience is to look like. Without these considerations, the injection mold tool design won’t fully serve its purpose.

Processing also must be considered in the injection mold tool design. How the molten plastic enters, fills, and cools within the mold to compose the part will be predicated on the form that the part’s features will take on. When the right approach and tool is in place, your ability to have a faster and easier manufacturing process will be attainable. One way Laszeray minimizes or eliminates molding problems is by dividing a part into specific groups that facilitate a logical build approach while forecasting any molding problems that may arise, followed by a swift course of action to ensure the process is flawless. This process also helps to minimize stress on parts, and to improve the overall quality.

Injection Mold Tool Design Support for Manufacturing

Every project will have its unique goals and objectives, and as a result there are several capabilities that can play into the injection mold tool design project. Laszeray is the go-to injection mold tool design provider for manufacturers because we offer any service one could possibly need, all under one roof. These include the following:

Call Laszeray for All of Your Injection Mold Tool Design and Manufacturing Needs

Laszeray Technology not only provides clients with the best injection mold tool design services for manufacturing, but we also offer several other services that often interplay with injection mold tool design such as CNC machining and other manufacturing services necessary for parts that require multiple components with unique manufacturing processes. We have decades of experience serving a wide range of industries that stretch from aerospace to medical, and from consumer goods to oil and gas. We have our own tool shop located in the safe confines of our ISO 9001:2015 certified, temperature-controlled production facility manned by the best expert teams in the industry. Call today to get a quote and learn how a partnership with Laszeray can refine your manufacturing process to speed up production times, cut costs, and enhance efficiency across the board.