Investment Casting Tooling

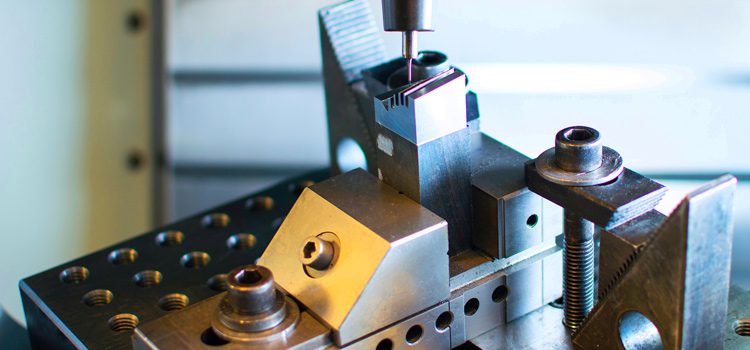

Tooling is an essential part of the manufacturing process. While tooling in metal casting and CNC machine tooling falls into place with reusable components specific to each individual job, investment casting tooling uses wax-injection dies that create wax patterns. The basis for the investment casting process relies on the wax patterns. There are a number of reasons why organizations partner with a company specializing in investment casting tooling for manufacturing. For example, investment casting tooling uses ceramic molds that produce a much smoother finish generally averaging around a 125 RA surface finish. The production process is also faster than other options, is highly affordable, size ranges are broad, there is a wide material variety, and tighter tolerances.

What is Investment Casting?

If you are relatively new to the industry, you may need to get a better understanding as to what investment casting is to better understand this type of tooling. Investment casting is a lost-wax casting industrial process with roots stemming from one of the oldest metal-forming techniques from the halls of history. The term “lost wax casting” simultaneously nods to modern investment casting processes used for products in a wide range of industries. Investment casting is roughly 5,000 years old, and Laszeray is known as the best investment casting tooling provider in the US, with decades of experience in serving organizations ranging from the aerospace industry to medical devices, and from consumer products to military and defense.

What are the Benefits of Investment Casting Tooling?

Manufacturers and craftsmen have been using investment casting tooling for decades because it has had the long-standing reputation as a reliable, highly regarded process. Investment casting tooling offers a plethora of benefits making it ideal for multiple industries and applications. Following are the top eight advantages of investment casting tooling by Laszeray Technologies:

Laszeray Technologies brings these benefits and many more to companies seeking investment casting tooling in their manufacturing process, and our engineering team will work with your team to help make design improvements, if necessary, during the manufacturing process from start to finish.

Are there Any Disadvantages to Investment Casting Tooling?

Any manufacturing process will have its fair share of disadvantages, based on the nature of the project. However, with investment tool casting, these disadvantages are far and few between. However, one clear disadvantage hangs over the heads of companies requiring large parts, as investment casting tooling has size limitations. Few design engineers can produce large parts using this technique. However, Laszeray has a history of being able to achieve this obstacle. In the past we have manufactured large parts using investment casting tooling that other organizations were unable to fulfill, so when you contact us for a project quote and for more information, and you require large parts, we may be one of the few organizations offering investment casting tooling for large parts that can accommodate you.

Investment Casting Tooling for Your Manufacturing Needs

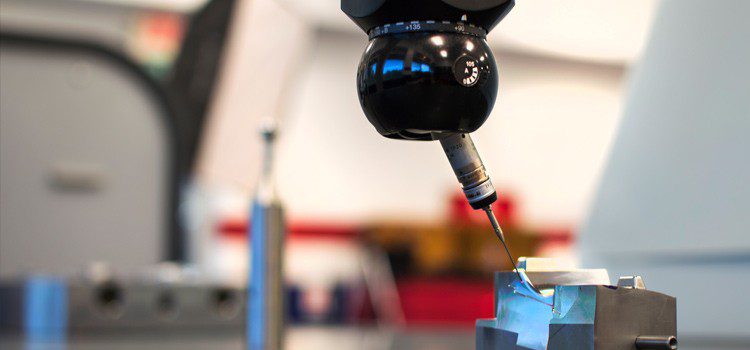

Investment casting tooling, also known as precision casting and lost-wax casting, is often the best available method for creating intricate parts and components. In industries where precision can mean the difference between life and death (like in the medical and defense industries), customers count on Laszeray to provide the investment casting tools they need.

As a leader among investment casting tooling and precision casting companies, Laszeray offers you and your organization its services and years of experience as a world-class designer and manufacturer of high-quality custom tooling for a wide variety of sectors. For example, Laszeray is a leading producer of investment casting tooling used to manufacture 3-D blades and vanes for the aerospace industry. In addition, we serve other industries where precisely fabricated parts and components are vital, including the medical, electronics, oil & gas, agricultural, and automotive sectors.

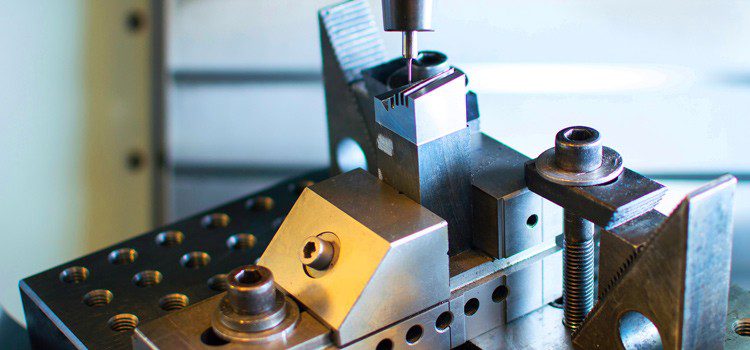

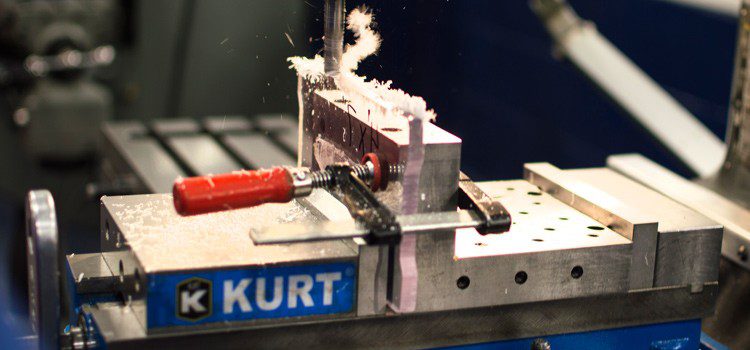

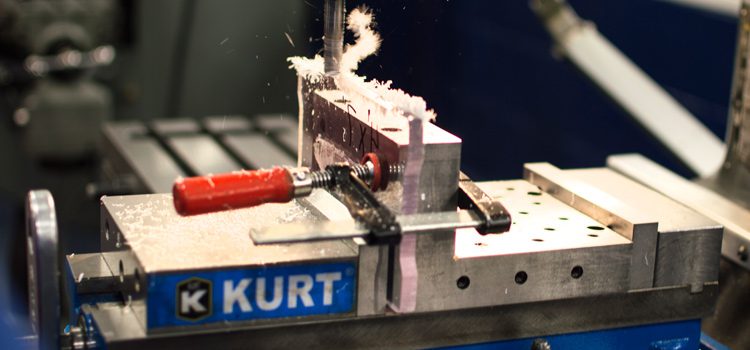

Investment casting tooling is a time-honored manufacturing process that can create components of virtually any level of complexity at tight tolerances. The investment casting coating process involves dipping a wax pattern into ceramic slurry to form a mold. From there, the wax is melted out and molten metal is poured inside. Once the metal has solidified, the mold is removed.

Whether you need to produce a tiny 1 oz. part or a large item weighing 20 pounds or more, investment casting gets the job done reliably, and at a reasonable price. As a manufacturing process, it’s flexible enough to produce large runs of a given part or just a few. In many cases, investment casting is the only truly cost-effective method of manufacturing a certain part or component.

Why Do Organizations Seek Investment Casting Tooling at Laszeray?

Investment casting tooling performed by Laszeray provides production advantages that include the following:

When you contact Laszeray, our specialists will be able to tell you if investment casting tooling is the right manufacturing approach for your project, and we can work with your team to achieve your goals ranging from cost-saving changes to completing critical tasks within your deadline.

Be sure to ask questions about the complexity of projects in the portfolio of the injection molding company that you consider. Think about the different materials they have experience with and the variety of machinery that can be used to produce the best results. When it comes to plastic injection machines, there are no one-size-fits-all solutions.

Contact Laszeray for the Best Investment Casting Tooling

Laszeray’s in-house talent, advanced equipment, and unique knowledge provides significant advantages to those seeking the best investment casting tooling who partner with us. We offer everything from rapid prototype investment casting for businesses that need to test a product design, to medical investment castings for healthcare facilities that demand precision-crafted tools. We pride ourselves on being one of the leading investment casting companies around. Feel free to contact us for additional info on our investment casting tooling capabilities. Laszeray’s systems include”

Give us a call today and learn how Laszeray’s investment casting tooling can help your organization hit its growth goals with affordable, time-saving high-quality investment casting tooling services.