CNC Production Machining

Computer Numerical Control, commonly known as CNC, is a machining process that involves computer-guided machine tools to produce high-quality parts.CNC is one of the leading technologies used by innovative tool and die manufacturers. Leading CNC machining companies enable operators in the tool and die making process to control the movements with total accuracy and efficiency. Common tools used in CNC production services include lathes, crane lifts, mills, routers, and grinders. Laszeray is proud to offer cost-effective services to organizations seeking a dependable CNC production company.

Benefits of CNC Machining for Production

CNC machining confers a number of valuable benefits. It can produce metal and plastic parts with very tight tolerances. A well-managed CNC production company like Laszeray can also handle low- and high-volume machining, granting the flexibility of using this technology to offer everything from a rapid prototyping service based on customer concept models to manufacturing services that can yield large runs of field-ready products.

Why Choose Laszeray for CNC Machining?

There are several reasons why organizations partner with Laszeray for CNC production machining. Laszeray boasts an extensive machining operations facility that provides post-molding machining as well as full-service CNC production machining. Our broad range of capabilities allows us to offer a wide variety of machining, drilling, and finishing operations for a broad spectrum of materials including steel, stainless steel, plastic, aluminum, and exotic materials.

Product development teams and other leadership teams invest with Laszeray because we offer state-of-the-art high-precision CNC machining equipment that comes with an array of advanced features, such as pallet changing, high speed operations, and four-axis and five-axis capabilities which allows us to deliver efficient, low-cost CNC engineering services.

LASZERAY’S PRODUCTION CAPABILITIES RELY ON A VARIETY OF IN-HOUSE SERVICES AND MACHINES:

Technical:

CNC Production Machining

Computer numerical controlled machining delivers, precise, consistent results. It is ideal for low- and medium-quantity production runs.

Haas High Speed 4 and 5 Axis Milling Centers

Haas High Speed 4 and 5 Axis Milling centers offer plug-and-play 4 and 5 axis tool capability. This allows for increasingly complex machining operations on multiple axes without the need for specialized mills.

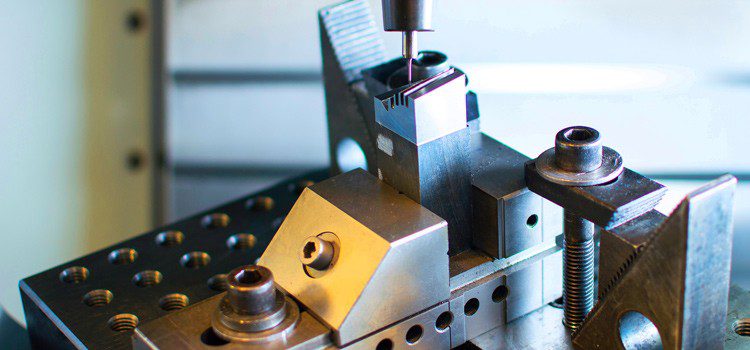

Haas CNC Turning

CNC turning is the precision process in which bar material is machined on a rotating plane with a single tool that removes material to create the desired shape.

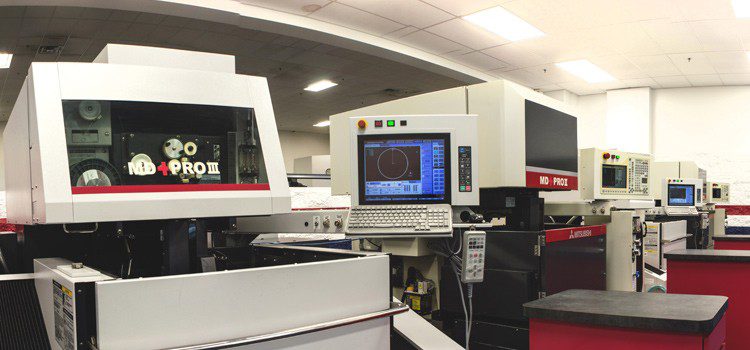

Mitsubishi Large Capacity Wire EDM Machines

With Mitsubishi’s proprietary Cylindrical Drive Technology—the most advanced linear drive available—the Wire EDM machine can produce precise cuts without wear, cogging, or backlash. The Mitsubishi Large Capacity Wire EDM is ideal for hardened steel tool and die making.

MD Pro III wire EDM – Specifications

Table Size: 25.2″ x 17.7″

Maximum Workpiece Dimensions: 31.9″ x 27.6″ x 8.5″

Maximum Workpiece Weight: 1102 lbs

Machining Stroke ( X x Y x Z ): 15.7″ x 11.8″ x 8.7″

U/V Travel: +/- 2.4″

Taper Angle: 15 deg @ 8.0″

Rapid Traverse: 51.2 ipm

Wire Diameters: .004″ – .012″

Wire Spool Size: 22.2 lbs

Wire Guide Type: Round Diamond

Minimum Start Hole Diameter: 0.02″

Dielectric Tank Capacity: 145 gal

Dielectric Filter Type: Paper Cartridge

Machine Weight: 5952 lbs

Machine Size: 77.7″ x 81.6″ x 80.2″ tall

Power Requirements: 200-230V [13.5] Built-in AVR

Products Made by CNC Machining

The products made by a CNC machine can be endless, and many of them are objects we see on a daily basis without giving them much thought. CNC machining technology creates items like pens, tyre rims, components for scuba diving equipment, ventilators, guitars, lamps, curtain rods, airplane engine parts, tennis racquets and thousands of other things we take for granted. CNC machining enables engineers a great deal of ease and speed in producing wood, metal and plastic parts in a safe, efficient and economically sound manner that is well above the bar when it comes to other production methods.

Industries Best Suited for CNC Machining

CNC machining is suitable for virtually any industry. However, the speed and precision of this manufacturing method makes it a particularly ideal fit for the aerospace, healthcare, transportation, automobile, retail product development and defense industries. In some cases the parts made by CNC machining are intricate and very delicate, and in other cases they are basic and flexible, or robust and solid. Savvy organizations seeking reliable, fast, affordable and efficient options for producing machined parts almost always partner with a CNC machining service provider that helps guide clients in the right direction.

Types of Machines Uses in CNC Machining

It is important for organizations to familiarize themselves with both the old and new CNC Machining methods that are available so they will know what direction to take in determining the option that will best suit the materials that are to be worked with. When you call Laszeray for CNC machining services our specialists will walk you through the available options, which include these:

Call Laszeray for Your CNC Machining Production Needs Today

For nearly 30 years Laszeray Technology has been providing multiple industries with high-quality, affordable and timely CNC machining services for production. All of our tooling is designed in-house, and we have one of the strictest quality control standards in the industry having been ISO 9001 certified since 2009. Give us a call today, and learn how a partnership with Laszeray can take your production needs to the next level and beyond.