Rapid Prototyping Services

When organizations want to get their product to market before their competition can even pull the trigger, they partner with Laszeray for rapid prototyping services to manufacture parts for component functionality and the right fit. During the prototyping process adjustments can be made to materials, design, shape, size, color, strength, and manufacturability following the results of the initial analysis and testing.

Laszeray’s rapid prototyping services draw upon a number of cutting-edge manufacturing techniques, providing customers with a high-quality full-scale prototype within hours once the product’s design has been conceptualized.

For more robust product designs, the company’s state-of-the-art in-house tooling shop can quickly develop initial production tooling capable of generating low-volume production runs. These capabilities allow customers to quickly and fully evaluate the function and appearance of their new product’s rapid prototype design before moving forward to normal production runs.

While most rapid prototyping companies use traditional manufacturing methods to produce prototypes, Laszeray uses the latest technologies and methodology to produce the highest quality prototypes with advanced design teams. There are many ways prototypes can be made, and when you partner with Laszeray our engineers help you and your leadership team select the best prototyping process, using the latest technology, for your product development cycle.

What is Rapid Prototyping?

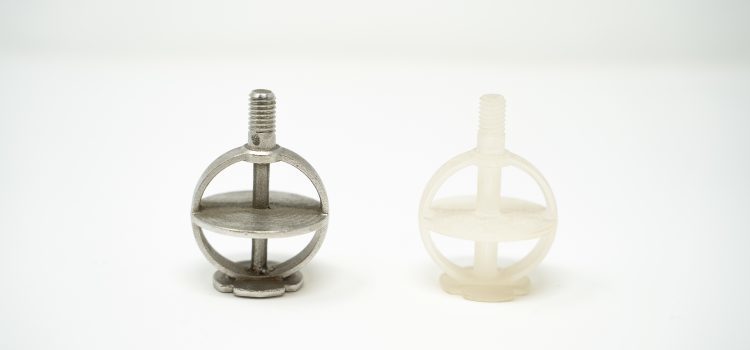

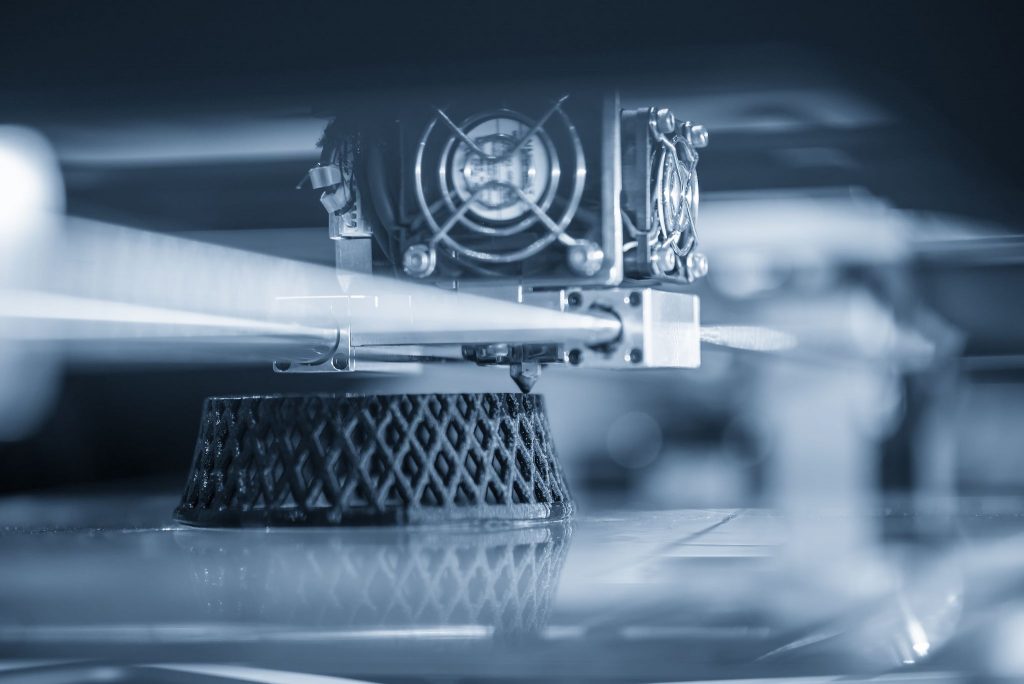

Many of our customers ask us to define rapid prototyping. Rapid prototyping manufacturing—sometimes called rapid tooling—is a combination of techniques used to quickly create a model of a part using CAD data. Construction of the part can be achieved with CNC milling technology, 3D printing, or additive layer manufacturing.

Rapid prototyping is, for the most part, a new term and is the process of quickly producing prototypes that meet the visual and functional elements of an engineering product design. A successful prototyping project is predicated on these key factors:

A prototype is a preliminary type of the end-product that aids in evaluating the design while testing the technology and working principle at play while garnering product specs for real working systems.

Prototyping Companies and Laszeray

When it comes to prototyping companies, Laszeray stands out in the industry as having one of the best lead times and developmental processes customized to meet the needs of every unique project. Rapid prototype development allows the customer to analyze any design weaknesses, compare slightly different versions of a product, present a proof of concept to investors, or figure out how to improve the manufacturing process. Once changes have been made to the product design, it’s a simple matter to create another prototype with the updated features at a cost much lower than that associated with standard tooling. Lead times can be condensed significantly.

Machine Tooling Services and Prototype Manufacturing

Machine tooling is the process of shaping or machining metals or other rigid materials by cutting, grinding, shearing, boring and other forms of material deformation or removal.

The specific type of process employed will depend on a variety of factors, including the complexity of the part, the quantity of parts that must be created, and the desired quality of the prototype. The common machine tooling categories are as follows:

Machine tooling has a direct impact on product lifecycle, output capacity, pricing, and quality. Having the correct tooling in place is critical for the manufacturing process because if the tool doesn’t perform properly the product won’t be manufactured correctly. As a result, die, tool and mold manufacturers are critical to the overall success of the end product.

Call Laszeray for Machine Tooling and Rapid Prototyping Services Today!

Laszeray Technology offers cost-effective, custom rapid prototyping services and machine tooling to many organizations spanning dozens of industries. Give us a call today for more information about our cost-effective CNC machining, additive layer manufacturing, and 3D printing rapid prototyping services.