CNC Production Machining

We’ve written before about the advantages of wire EDM machining in mold making. Before getting started on your next project, there are several factors to consider for optimizing EDM productivity. First, it’s time to reevaluate the kind of wire you’re…

Read MoreIt is rewarding to know when Laszeray, as a company, invests in an entire factory floor full of Haas high speed, 4- and 5-axis milling centers, that not only have you purchased the best, American-made equipment on the market, you’ve…

Read MoreJust like Collider merged 3D mold making and injection molding in our May 19th blog post, Hybrid Manufacturing Technologies brought together two key manufacturing systems into one new technology. CNC Machining and Additive Manufacturing (AM) were combined, using both subtractive and additive processes, to develop specialty…

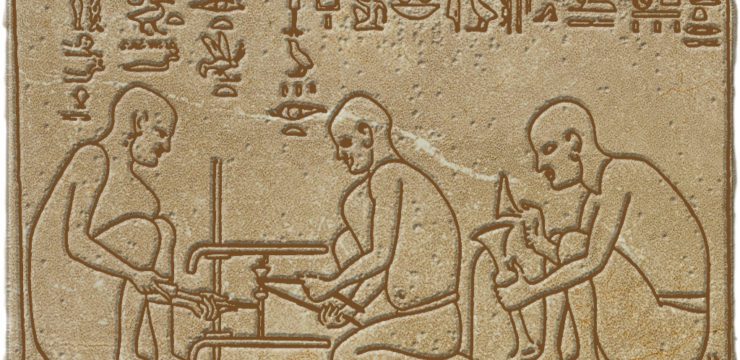

Read MoreFor those with a desire to go deep into the weeds on CNC manufacturing, we offer you this article from engineering.com. “An Engineer’s Guide to CNC Turning Centers” tracks and explains one of the most ancient manufacturing technologies on Earth. The level…

Read MoreWire EDM (Electronic Discharge Machining) is growing in popularity as a precision, cost-effective machining technique. Wire EDM cuts materials with electric current. A piece of wire is suspended between two electrodes in a tank of dielectric fluid; current running through…

Read MoreHaas Automation has been voted one of Technavio’s top five leading vendors in the global CNC horizontal machining centers. The largest machine tool builder in the western world, Haas automation produces high-quality CNC machinery in their southern California plant. Haas Automation milling…

Read More- « Previous

- 1

- 2