Custom Injection Molding

Multi-shot plastic injection molding is the process of injecting two or more plastic materials or colors into a single mold simultaneously to create a single part or component. The process can also be used with various materials besides plastics, such…

Read MoreWhen companies search for plastic components to fulfil a specific need, they need to partner with the best plastic injection molding company capable of making their part with 100% accuracy, to function flawlessly, and at cost. When choosing a plastic…

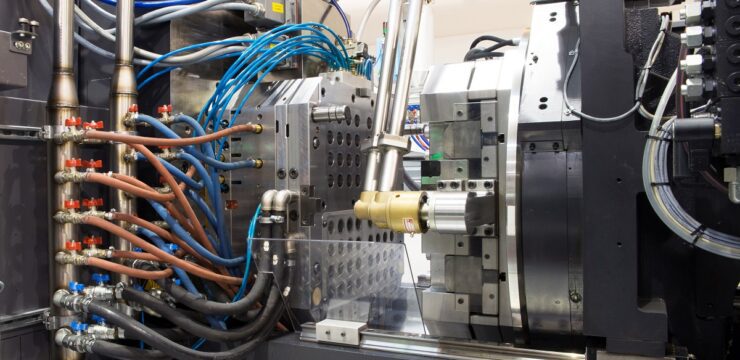

Read MoreInjection molding is an efficient means of manufacturing parts in high volumes. Most often used for thermoplastics and thermosetting polymers, it can be applied in the design and production of metal parts as well. Parts are produced by injection molten…

Read MoreWhen you are looking for a custom tooling company to help produce the parts and components you need, as well as take care of finishing processes, you need to understand what machines they have available. The types of machines they…

Read MoreTouch responsive interfaces are the future. We love them on our sophisticated electronics, but manufacturing cost is a barrier to entry for these types of interfaces becoming prevalent across the spectrum of consumer electronics. We’ve looked at in-mold electronics (IMEs) and touch-sensitive surface…

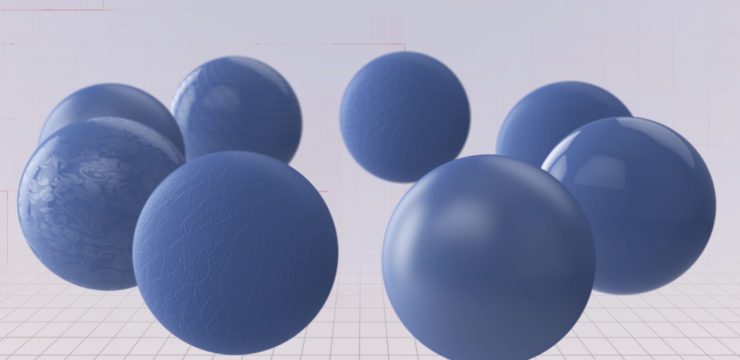

Read MoreInjection molded plastic parts and products can have many different surface finishes, all of which contribute to making your finished product exactly as designed. Watch our new video for a rundown of the choices and uses of texture. For more information,…

Read MoreThere’s a growing demand in the electric vehicle market for both personal cars and fleet trucks and busses. Much technology has advanced around these applications, with batteries themselves benefitting from an increased focus on development. One of the most promising…

Read MoreOne of the most promising technological developments in recent years, in-mold electronics are poised to change both electronics and plastics manufacturing. In-mold electronics are devices created by printing with conductive inks and transparent conductive membranes effectively creating an electronic “smart skin” that…

Read MorePlastics play a critical role in so many parts of our lives. Their combination of durability, light weight and adaptability have made them a cornerstone of modern manufacturing and technology. However, there can be a downside to many of the…

Read MoreImagine being able to add touchscreen-like control to any surface. Sounds like real science fiction, but a small group of engineers are working to make it happen. Their new product, called Electrick, uses electric field tomography with an electrically conductive material…

Read More