Injection Mold Design and Manufacture

Advantages of Using Plastic Injection Molding Plastic injection molding is used to make a wide variety of parts and products. There are various other plastic molding methods, but the advantages of injection molding make it the preferred method over others.…

Read MoreInjection molding is a manufacturing process compatible with almost any kind of plastic resin. It can yield parts in various sizes and levels of complexity, making custom injection molding possible. Production volumes can range from short runs to millions of…

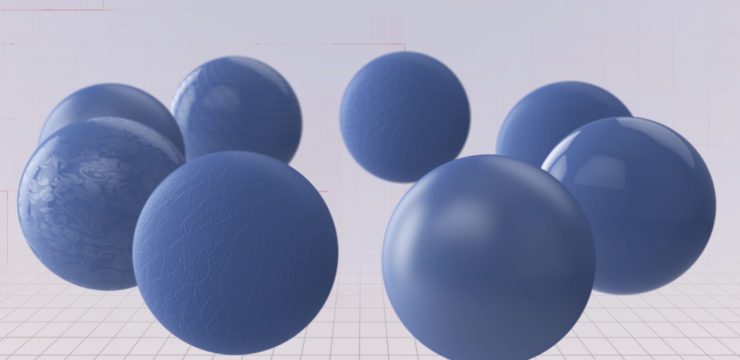

Read MoreInjection molded plastic parts and products can have many different surface finishes, all of which contribute to making your finished product exactly as designed. Watch our new video for a rundown of the choices and uses of texture. For more information,…

Read MoreThough relatively in its infancy, the merging of the manufacturing technologies of 3D Mold Making and Injection Molding is extremely exciting to see for the evolution of the industry. Congratulations to Collider for zigging while everyone else is zagging. At TechCrunch…

Read MoreAww! We have to admit, the APSX-PIM is a cutie! We think it would look adorable in a crib sitting between our 730 ton and upcoming 1000 ton Wittmann Battenfeld presses. In all seriousness, we think this compact version of…

Read MoreThis is an informative article from Plastics News with very promising indicators for the stability and growth of the injection molding industry. Making the best of prevailing conditions requires a clear vision of the value we deliver, a commitment to invest in advanced…

Read More- « Previous

- 1

- 2

- 3

- 4