Uncategorized

Are you in search of cutting-edge solutions for your plastic injection molding needs? Laszeray, offers a wide spectrum of mold capabilities that cater to your specific requirements. From injection molding presses with varying tonnages to advanced processes like multi-shot molding…

Read MoreLaszeray Technology, LLC has been selected as one of this year’s industry partners for the Master of Engineering and Management (MEM) program at Case Western Reserve University (CRWU). “Laszeray is extremely honored to have been selected as an industry partner…

Read MoreDuring the holiday season, Laszeray gives back by donating to the North Royalton Food Bank – a recent partnership between the city of North Royalton’s Office on Aging and Human Services, the Kiwanis Club and Royal Redeemer Church. Throughout the year, Laszeray…

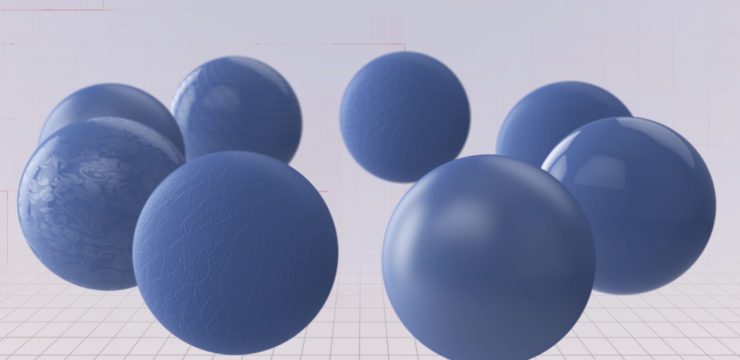

Read MoreInjection molded plastic parts and products can have many different surface finishes, all of which contribute to making your finished product exactly as designed. Watch our new video for a rundown of the choices and uses of texture. For more information,…

Read MoreWe’ve written before about the advantages of wire EDM machining in mold making. Before getting started on your next project, there are several factors to consider for optimizing EDM productivity. First, it’s time to reevaluate the kind of wire you’re…

Read MoreOhio has become a global leader in advancing next-generation manufacturing. Surprised? You shouldn’t be. Ohio offers industry leaders massive manufacturing output, unrivaled market access, investment in science and engineering, a talented pool of engineers and engineer techs, and a large…

Read Moreurrent economic indicators show that with low employment and churn rate (employee turnover/attrition rate), job stability has remained largely unchanged from 1950-2000 and has actually increased in the last 15 years. In fact, investment in automation is somewhat low, with only a…

Read MorePlastics play a critical role in so many parts of our lives. Their combination of durability, light weight and adaptability have made them a cornerstone of modern manufacturing and technology. However, there can be a downside to many of the…

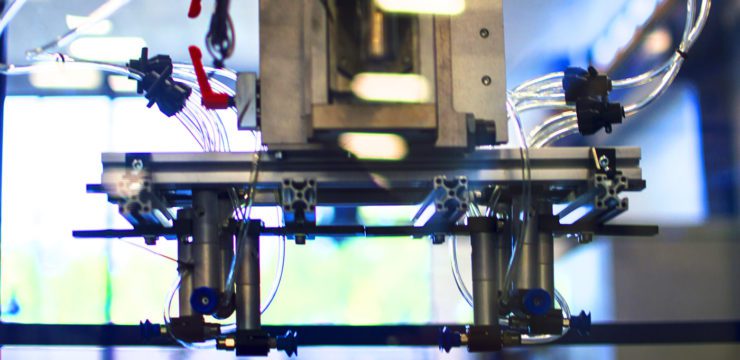

Read MoreRobotic End-of-Arm tooling (EOAT) is a critical automation technology that helps speed production, improve part quality, and meet demanding technical requirements. Robotic part handling with EOAT is a precise and safe way to ensure quality in the final stages of…

Read More